CoreSpec QMIN

CoreSpec is one of the few commercial labs in the world that can provide accurate mineral analysis for reliable petrophysics, reservoir quality, and related formation properties controlled by mineral content.

CoreSpec is one of the few commercial labs in the world that can provide accurate mineral analysis for reliable petrophysics, reservoir quality, and related formation properties controlled by mineral content.

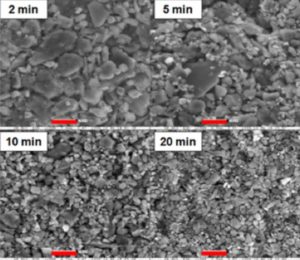

The most important aspect of core sample analysis is that many destructive laboratory measurements must be combined from different aliquot samples to obtain a wholistic understanding of formation lithologies. The first step in our approach is that a sufficiently large sample size must be selected to be representative of the formation bulk property, such a bulk sample is typically expressed as a down hole stratigraphic depth. Second, the chosen bulk sample volume must be ground to a size that can be homogenized and divided into mineralogically and chemically equivalent aliquots. Third, the goal is that any of the aliquots upon further processing will still be representative of the initial homogenized bulk sample. Środoń et al. (2001), McCarty (2002), and McCarty et al. (2014) successfully demonstrated that grinding in a non-shearing manner with minimum energy for a sample to pass through a 40 mesh standard sieve (<0.4mm), and then homogenized thoroughly and carefully divided, can produces aliquots that are chemically and mineralogically equivalent within analytical error.

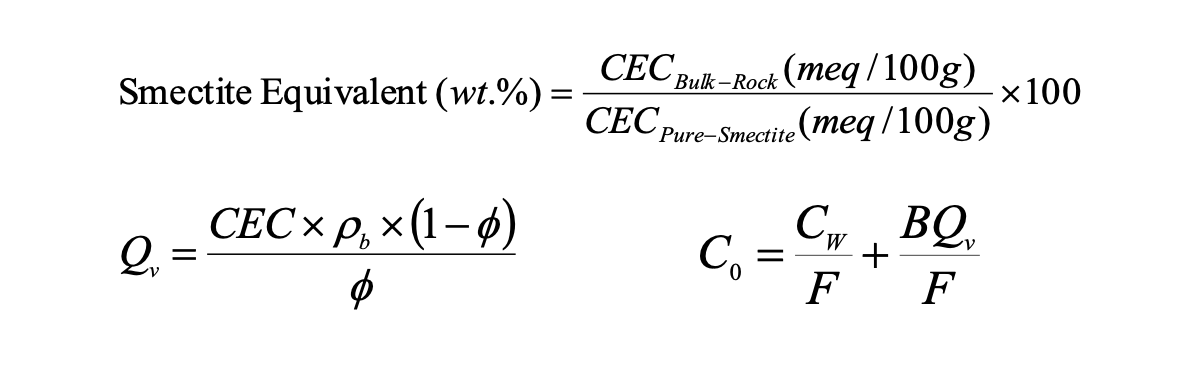

Cation exchange capacity (CEC) is among the most important physicochemical properties of sedimentary rocks. In the oil and gas industry, CEC values reflect the quantity of hydrated exchange cations, allows calculation of the mineral surface-bound water, and is used for various corrections and calibrations in wireline log analysis where CEC is employed in calculating effective porosity and permeability in hydrocarbon reservoirs (Derkowski et al., 2015). CEC is also important to hydrocarbon production, where it relates to formation damage potential, affects drilling and completion strategies, and is needed to design effective reservoir stimulation techniques.

CEC measurement by Co(III)-hexamine3+ cation exchange, and the spectrophotometric technique of Bardon et al. (1993), on 110ºC basis.

Quantitative phase and mineral analysis (QPA) of oil field core and cuttings samples is a key component of the energy industry for petrophysics and sub-surface formation evaluation. When done correctly QPA can help completion and production strategies and thus significantly boost estimated oil recovery (EOR).

After the three steps of (1), preparing a statistically random orientation of all the mineral particles, (2), that all particles are < 20 mm diameter, and (3), there is a narrow distribution of particle sizes (Figure 1) an XRD pattern suitable for quantitative phase analysis can be collected. Some of the successful methods of accurate QPA are described by Omotoso et al. (2006) and by Raven and Self (2017). The citations by these authors describe in detail the calculations, diffraction optics, and various software types that are used.

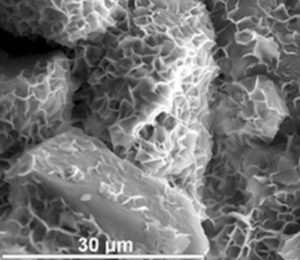

A detailed clay analysis is made by computer modeling and fitting the full oriented or basal experimental X-ray diffraction (XRD) patterns with those calculated for individual clay mineral phases in the sample. Oriented XRD patterns are different from common random powder (RP) XRD in that the clay minerals, which have plate-like morphology, are oriented parallel to the surface of the sample mount. While RP XRD provides peaks of all the three-dimensional crystallographic or hkl orientations, perfect oriented clay preparation result in only one-dimensional diffraction, also called the 00l or basal series of diffraction peaks, which are diagnostic of clay species and the layer proportions in mixed-layered clay types such as illite-smectite (I-S).

When XRF is done correctly and combined with quantitative phase analysis (QPA) of formation mineralogy, XRF can help the petrophysical calibration for multimineral evaluations. McCarty et al. (2014) describe non-linear methods to combine whole rock elemental data and QPA mineral data from X-ray diffraction (QXRD) to determine the average elemental composition of minerals with variable compositions and subsequently calculate the petrophysical response that each mineral has on standard wireline logs.

Elemental concentration calculations depend on running a series of appropriate calibration standards, where the elemental concentrations are known, under the same sample preparation processing conditions. XRF results from the preparation and analysis of the standards are introduced into CoreSpec’s instrument calibration mode and then require unknown samples to be processed in the same manner.